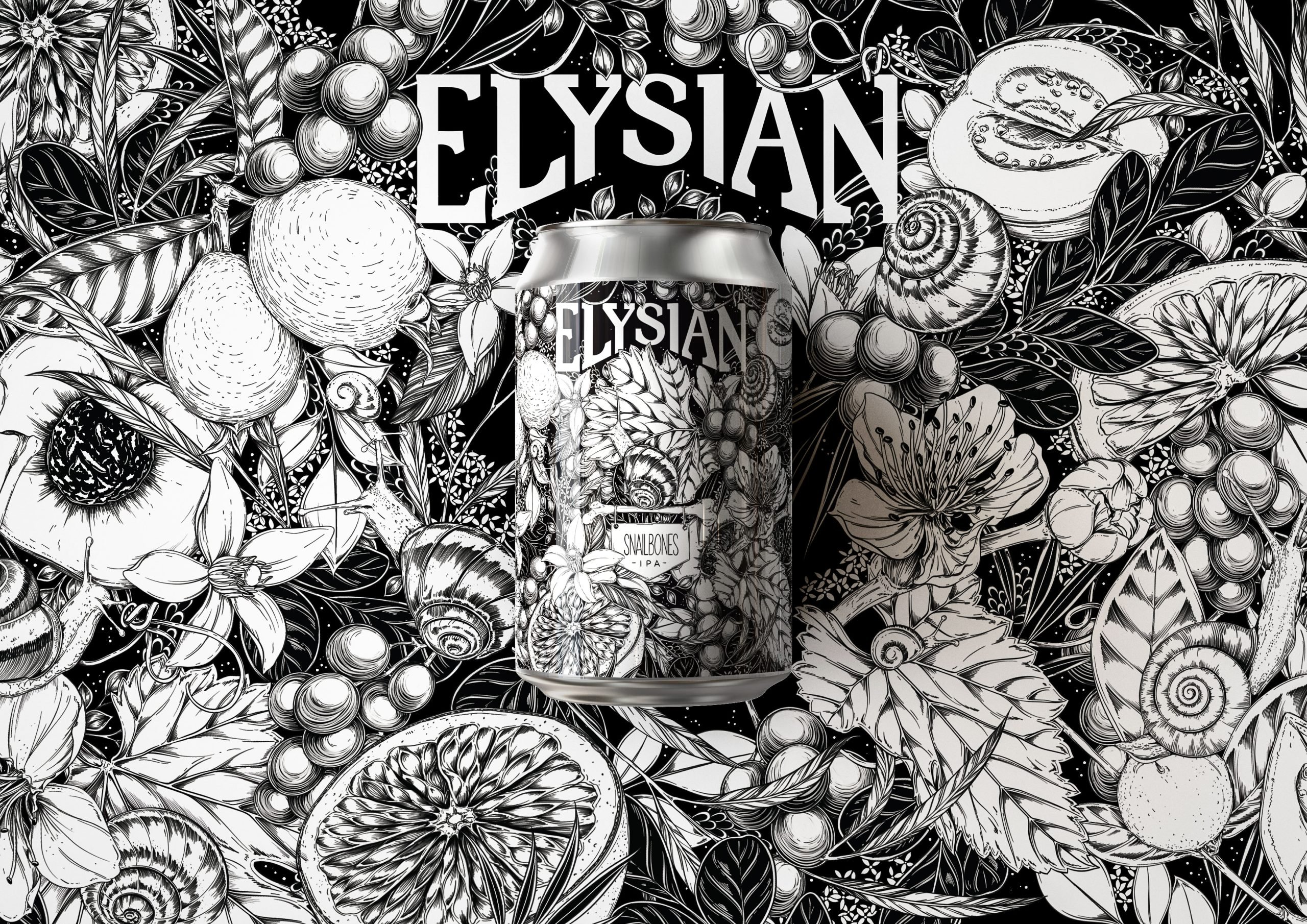

Aluminumâs strength, lightness, and resistance to corrosion has lead to the usage of the material in everything from planes to beverage containers, and unlike plastic, it is infinitely recyclable.

Over 96 billion cans are produced in the United States aloneâthatâs a lot of soda, beer and creamed corn. The automotive industry has increasingly turned to aluminum to meet stricter fuel efficiency standards as it has similar properties to steel but weighs half as much. Modern air travel would not be possible without aluminum as 75-80% of the plane you’re flying in is made up of aluminum.

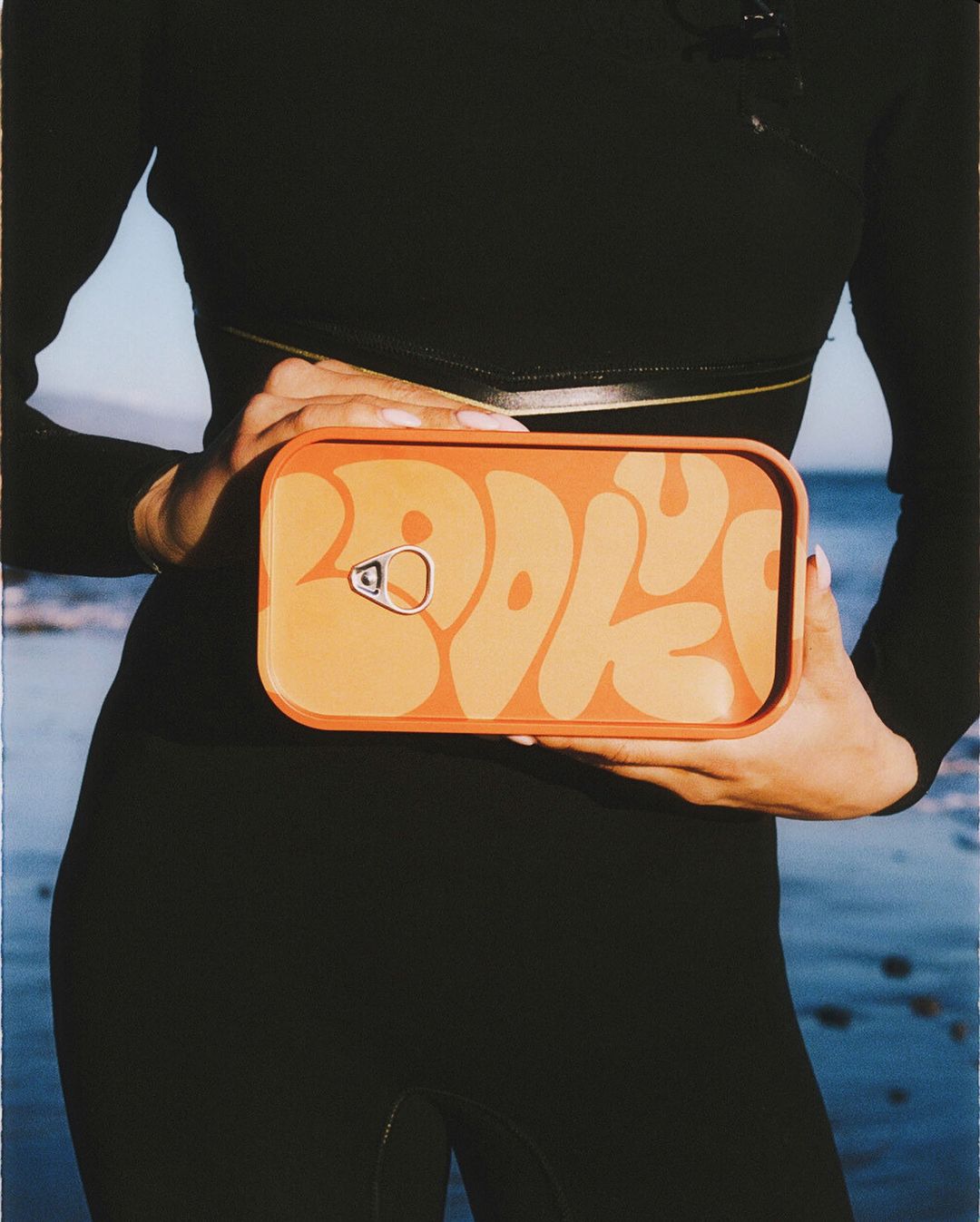

But as brands continue to set sustainability goalsâparticularly around using less plasticâsome are looking to aluminum as a greener alternative. But do the downsides of the metal outweigh the positives? Mining the substance comes with a steep ecological cost, and the rate of post-consumer aluminum that is put back into new products is subject to economic externalities.