Sneakerhead culture is very much alive and well, and our insatiable desire for kicks knows no bounds.

But what many folks might not recognize is that there’s also an incredible amount of waste in the shoe industry and that more than 300 million pairs of shoes get thrown away in the US each year. Once they hit the landfill, they take anywhere in the neighborhood of 30-40 years to decompose. However, the midsoles of your favorite sneakers get made with ethylene vinyl acetate, and that can take upwards of 1,000 years to fully biodegrade.

Kengos is a new earthy-friendly shoe brand looking to challenge the wasteful status quo, launching on Earth Day 2021. Their first pair of kicks—the Lace Up—goes live today, and they describe it as the shoe that “wears out slow, but breaks down fast.” By consciously considering the environment it gets manufactured, Kengos wants to push the industry forward and challenge how we produce shoes.

Your typical pair of sneakers are made with more than 20 components and can involve more than 300 steps in the manufacturing process. Kengos keeps it pretty simple with a knit upper made from eucalyptus, a natural cork footbed, a Pure Flex rubber outsole, and corn in the laces and webbing (corn is also a part of the knit upper). They don’t use nylons or polyesters, adhesives, animal products, or synthetic rubbers, and the shoes get made with their patented 1knot construction. That way, they can get easily disassembled for recycling at a later date. Currently, the brand is 87% plant-based, but they intend to reach 100% by the end of 2022.

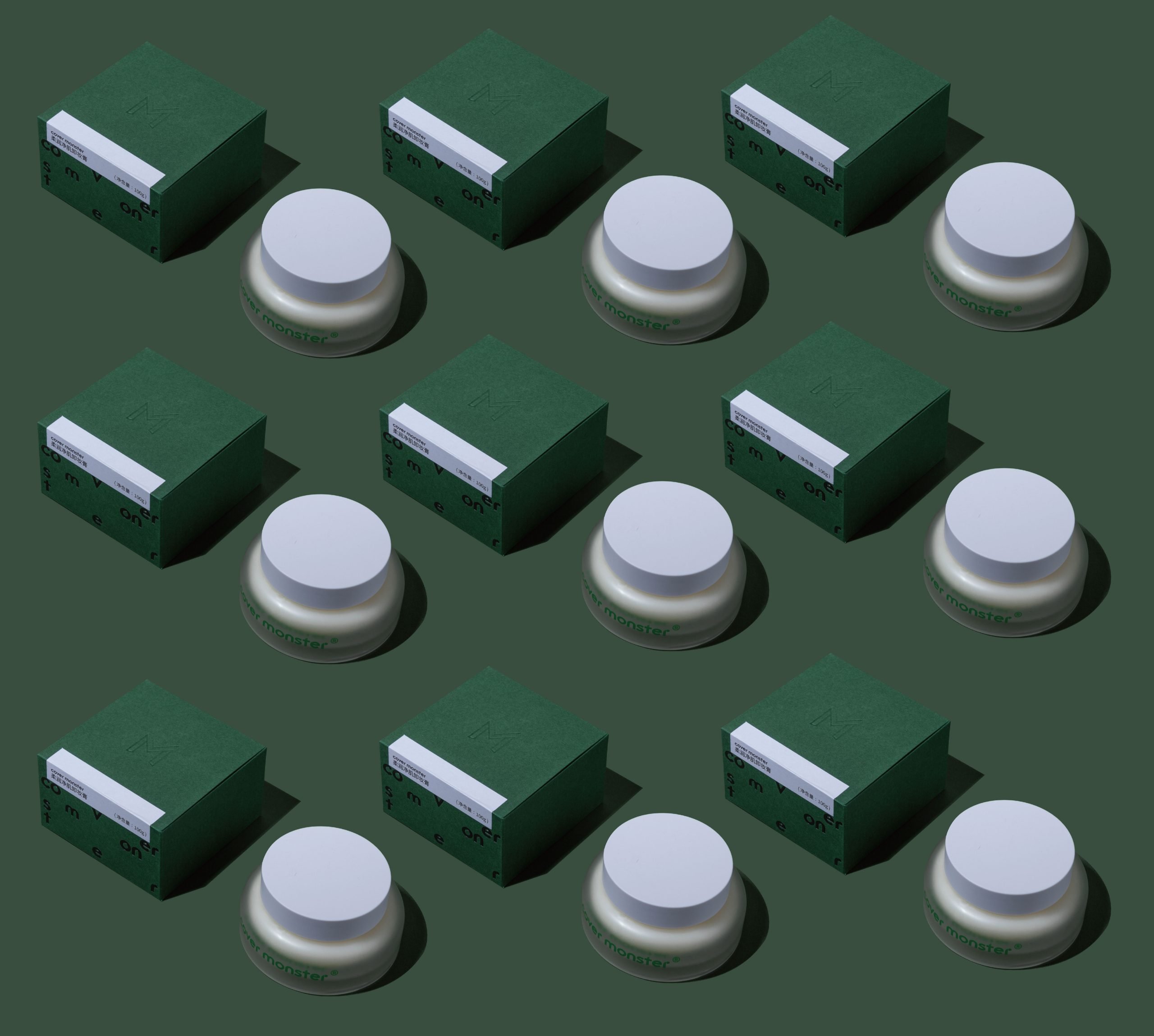

To help launch the sneaker upstart, Kengos worked with New York City-based branding and design agency The Working Assembly to create the visual identity and packaging.

“Many brands that say they’re sustainable need to push the traditional sustainability tropes–earthy, neutrals, organic, and clean,” says Rachel Wilkinson, Working Assembly lead designer on Kengos. “So the fun problem to solve became creating an identity that stood out without falling into the typical sustainability symbols.”

You could best describe the logo as “perfectly imperfect.” With its handwritten wordmark, they not only incorporate the 1knot whipstitching process used in making the shoes but our own human nature, giving it a personal feel that highlights the handcrafted quality. That theme of imperfection gets weaved throughout the design system, as well as a spotlight on what is human-made and nature-made. Iconography uses organic shapes and geometric lines in harmony, while art direction uses natural environments paired with vibrant colors that you can’t really find in nature.

The packaging also does a lot of the sustainable lifting for the brand. If you think about it, when you order a pair of shoes, they come inside a box with tissue paper, cardboard inserts, plastic baggies, tags, and a whole lot of other material you don’t really need. Oh, yeah, and that shoebox is usually shipped inside another box.

Here, The Working Assembly stripped down the unboxing experience to the essentials. For starters, they used recycled cardboard for the packaging and as minimal dimensions as they could. The box the shoes come in is also the shipping container, and they managed to do away with tapes and adhesives while also utilizing plant-based inks. The box also features a tearaway strip that takes elements from the shoe’s trademark whipstitch look, as well as a colorful illustration of the sneakers. Inside, consumers are greeted by the brand’s messaging around sustainability and the materials that comprise the shoe.

“Leverage design to eliminate waste,” says Dave Costello, Kengos founder. “This is the way we approached the entire product design and development process, and our approach to packaging was no different. We partnered closely with The Working Assembly to eliminate as much material as possible from our packaging while achieving the intended outcome, protecting our shoes during delivery, and communicating our brand ethos to our consumers.”

By minimizing the components in the shoes and packaging, Kengos provides the industry with a roadmap to create a shoe that’s genuinely better for the environment. And when you’re all done, you can send it back to them, where they recycle as much of the shoe as possible, using pieces to help create new shoes and keeping as much as they can from going to waste.

“Rarely does a company come along that actually challenges the status quo in a truly positive way,” says Lawrence O’Toole, The Working Assembly head of design. “Kengos does just that, and the team was open to fresh ideas around how to reflect their authentic ethos through visual identity and packaging. It’s been incredibly satisfying for us to deliver a brand system that delivers on and extends this disruptive nature.“